Wedding Stationery Guide: Letterpress Printing

Letterpress printing. Whether you’ve never heard of it, or you have been head over heels in love with it since you first came across it, this printing process is undeniably gorgeous. But how in the world does it work? And why is it so much more expensive than flat printing? I’m answering these questions and more in this installment of the Wedding Stationery Guide! Letterpress is my all time favorite printing process – nothing compares to its look and feel. It effortlessly elevates a traditional wedding invitation from plain to elegant, and instantly transforms a simple typographic design into a work of art.

If you’ve never had the opportunity to hold a piece of letterpress stationery, order a sample pack so you can run your fingers over the paper and see its beauty for yourself.

As part of the Wedding Stationery Guide, I’ve put together a primer on printing processes to clear up some of the confusion that comes with ordering wedding invitations. See other posts in the series here: Printing Primer

Letterpress is an artisan printing method that results in a deep impression on soft cotton paper. It’s a time honored technique, making it perfectly suited to producing elegant and traditional letterpress wedding invitations.

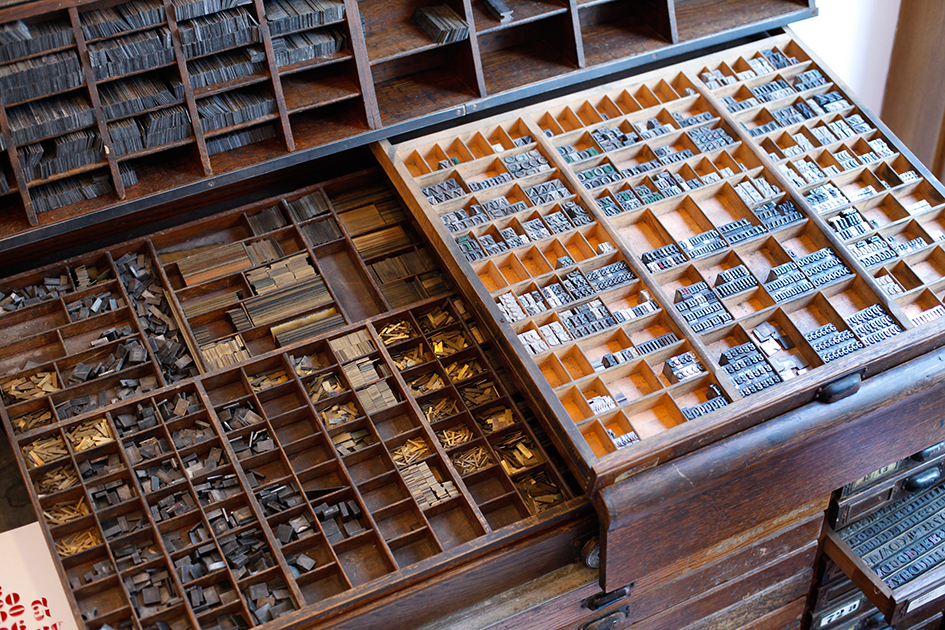

In letterpress printing, ink is transferred from a raised surface to paper using pressure. Originally, printing was done using wood type set by hand. While some printers still use movable type, all the invitations I offer are printed using a custom made printing plate. This means I can create custom designs on my computer using the typefaces and embellishments you choose.

Once the layout for an invitation design is finished, the digital artwork comes to life when it’s made into a polymer plate. A separate plate is created for each ink color used in the artwork. Ink is applied to the plate, paper is hand fed through the printing press. The plate is pressed into the paper, creating an inked indentation.

Letterpress inks are mixed by hand, printing plates are manually aligned, and old presses have their quirks. This is all part of the beauty of letterpress, and means that there will be slight variations between the pieces in your order.

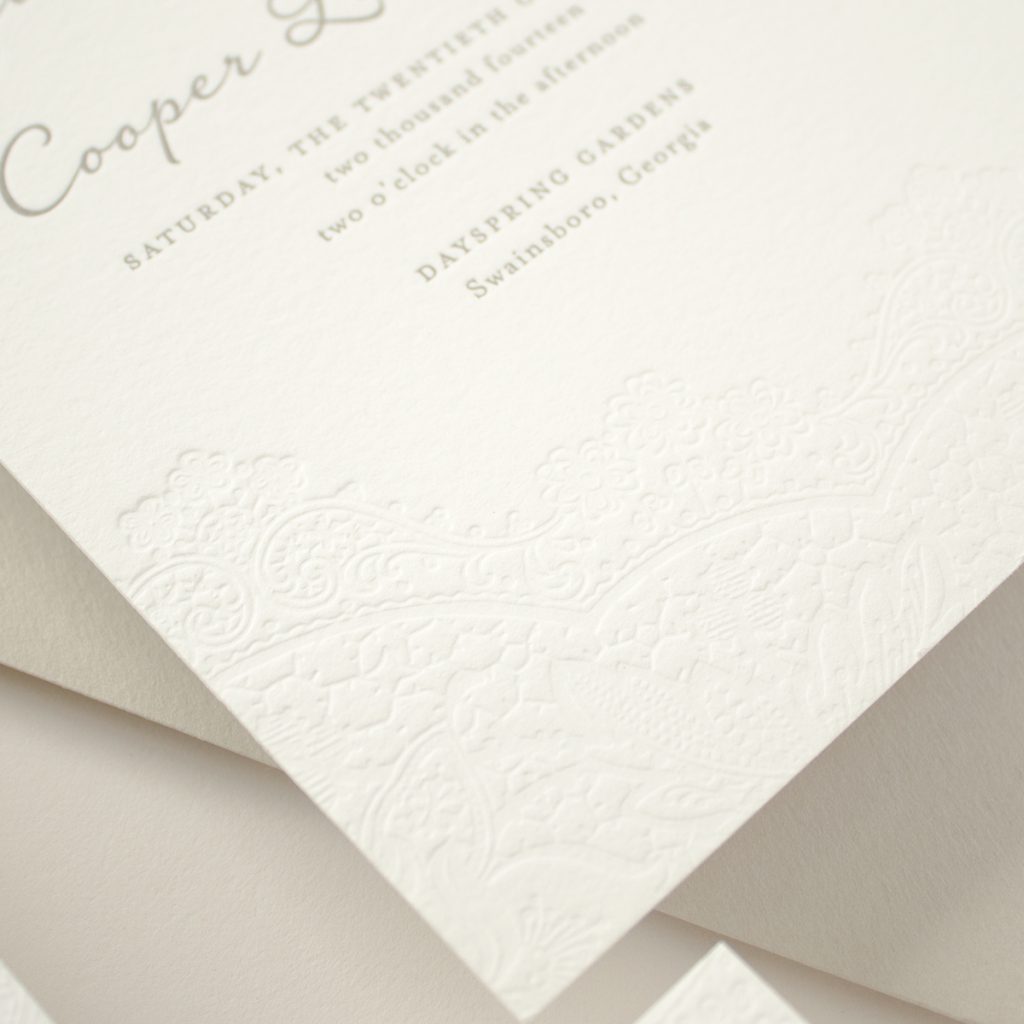

Blind letterpress (also referred to as “blind impression”, “embossing” or “debossing”) is the technique of letterpress printing with an un-inked plate to press a design into the paper. The result is a subtle texture without color. Because a separate printing plate is made for blind letterpress*, it counts as a “color” for pricing purposes.

Letterpress is a labor intense process. Most of the costs are in the set up, so the cost per piece for low quantities is high. Conversely, the higher the quantity the lower the cost is per piece.

Letterpress printing is best suited for two or three color designs with minimal ink coverage. Soft cotton paper allows for the best impression, but letterpress is also available on smooth paper stocks (there will just be a less noticeable indentation in the paper). The letterpress collection showcases designs that are perfectly suited to this classic printing method. I’m happy to adjust other designs to work with letterpress printing too!

Letterpress can also be paired with foil stamping – as seen in the Delicate design below, featuring blind letterpress with rose gold foil stamping.

Hopefully this post and the photos gave you a better understanding of letterpress printing. However, I think letterpress needs to be seen in person to be truly appreciated! Head over to the shop and order a sample foil wedding invitation so you can run your fingers over the deep impression in the paper and see its beauty for yourself.!